Maintaining Your Osmonics Equipment: The Importance of Replacement Parts for Longevity

Water treatment systems are crucial for ensuring the purity and safety of water used in various industries and domestic settings. Within these systems, Osmonics equipment plays a key role in achieving high-quality water processing. Given the complexity and constant use of such equipment, it’s imperative to focus on regular maintenance and timely replacement of parts to avoid costly downtime and ensure system longevity. In this article, we’ll delve into the importance of understanding, maintaining, and procuring the right components for your water treatment machinery.

Understanding the Role of Osmonics Equipment in Water Treatment Systems

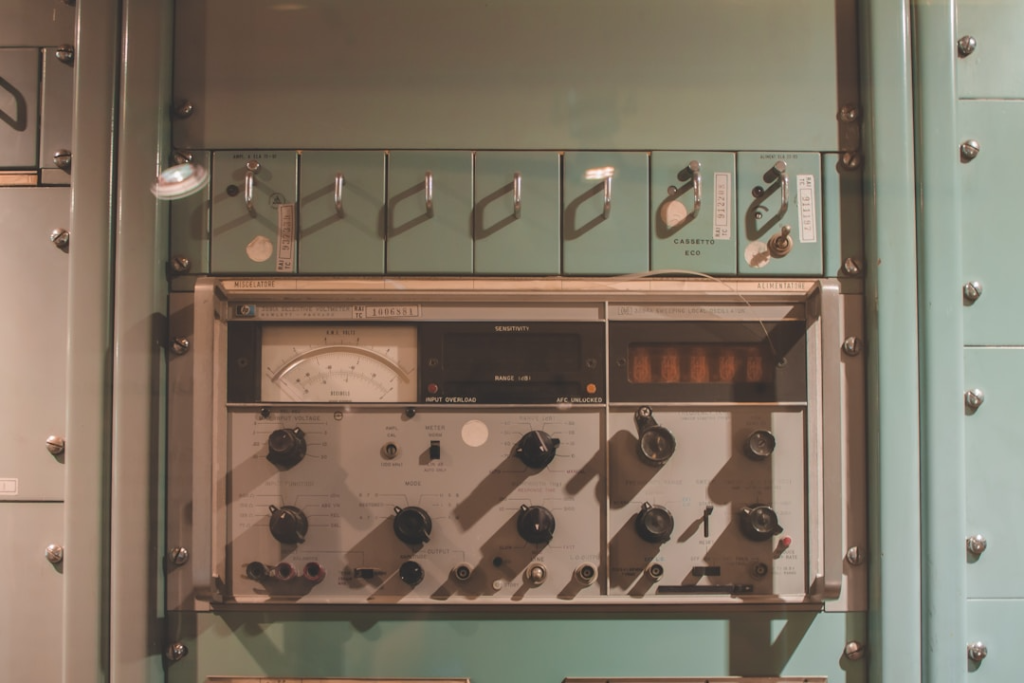

Osmonics is recognized as a leader in the water treatment industry, offering products from filtration systems to reverse osmosis units. The reliability of these systems is critical for delivering clean water and supporting operations across various sectors. Continuous use subjects components to wear, making it essential to understand their functions and stresses.

Operators benefit from knowing how every element, from valves to control modules, contributes to system efficiency. As water scarcity, pollution, and regulatory standards increase, maintaining equipment in optimal condition protects public health and prevents operational or reputational risks. Awareness of each part’s performance is key to extending system longevity and sustaining water treatment processes.

Recognizing Signs of Wear: When to Consider Replacing Parts

Even the most durable systems experience wear over time, influenced by factors like water quality, usage frequency, and maintenance routines. Operators should watch for early warning signs, including drops in system pressure, unusual noises, or changes in water quality, which may indicate the need for inspection or part replacement.

Educating staff to recognize these signs and performing regular checks of performance data and physical components helps prevent costly issues. Some parts, such as membranes, filters, and O-rings, endure constant stress and require frequent monitoring. Understanding the difference between normal wear and potential failure allows for timely replacements, protecting system integrity and ensuring consistent operational performance.

The Impact of Regular Maintenance on Osmonics Equipment Performance

The performance of Osmonics equipment depends heavily on consistent and high-quality maintenance. Adhering to scheduled upkeep preserves functionality, extends lifespan, and prevents costly downtime or system failures. Routine maintenance includes cleaning, replacing worn components, and updating software, allowing early detection of potential issues.

Properly maintained systems also operate more efficiently, consuming less energy and reducing operational costs and environmental impact. Maintenance budgets are a small fraction of the potential cost of failures. Beyond operational efficiency, maintenance ensures safety, protecting both operators and end-users. Keeping equipment in optimal condition supports reliable water treatment, safeguarding health, resources, and overall system performance.

Identifying Quality Replacement Parts for Osmonics Systems

Using high-quality replacement parts is essential for maintaining Osmonics equipment. While cheaper components may seem cost-effective initially, they often wear out faster and can cause further system damage. Choosing top Osmonics equipment parts from trusted suppliers ensures compatibility, durability, and consistent performance, protecting your investment in the long run.

Reliable suppliers not only provide genuine parts but also offer expert guidance and maintain comprehensive inventories. This reduces downtime by making the right components readily available and helps avoid system failures, inefficiencies, or voided warranties. Investing in certified, high-quality parts keeps your equipment running smoothly with minimal disruption.

Read also: Benefits of Using Laser Technology in Custom Design

Implementing a Sustainable Maintenance Routine for Equipment Longevity

A consistent maintenance routine is essential to prevent premature system failures and operational disruptions. Establishing a schedule based on manufacturer guidelines and operational demands ensures equipment longevity, covering filter and membrane replacement, electrical checks, software updates, and system calibration.

Involving staff in the maintenance process fosters responsibility and equips them to perform regular inspections while recognizing when professional service is needed. Thorough documentation of all maintenance activities supports tracking part lifecycles, planning future work, troubleshooting, and warranty claims. Regularly reviewing and adjusting the maintenance protocol ensures it continues to meet the changing needs of the system, maintaining optimal performance as the equipment ages.

Overall, the meticulous maintenance and timely replacement of parts are non-negotiable elements in managing Osmonics equipment. By underscoring these practices, organizations can ensure their water treatment systems continue to operate reliably, protecting their investment and fulfilling important health and regulatory obligations.